Wind Turbines are emerging as the most promising clean energy technology for the fossil fuel-addicted world. Currently, it costs less per kilowatt of energy than solar power which is reflected in the growth of wind energy generation by 31.7 percent in the last year to reach a respectable 2 percent of the global energy output. If this growth rate is sustained, wind energy would double every three years.

Wind Turbines are emerging as the most promising clean energy technology for the fossil fuel-addicted world. Currently, it costs less per kilowatt of energy than solar power which is reflected in the growth of wind energy generation by 31.7 percent in the last year to reach a respectable 2 percent of the global energy output. If this growth rate is sustained, wind energy would double every three years.

As we know it

The typical wind farm consists of horizontal axis wind turbines made of aerodynamically designed blades of fibreglass composite materials with a sweep diameter of 30 meters to 80 meters mounted on hollow steel tubular or lattice work steel towers that range in height from 25 to 75 meters. When the wind blows, the rotor blades rotate at 10 to 30 revolutions per minute and generate electricity. Such a wind turbine typically would produce around 800 kilowatts of power at wind speeds of about 15kph. Larger wind turbines, with power output upto 5 Megawatts have also been commercialized which have sweep diameters of over 110 meters and correspondingly taller towers. Modern wind turbines are provided with pitch and yaw controls so that the turbine blades can be moved to face the wind direction (within a narrow range , of course) to optimize power output .

Need for change

While wind energy has the advantage of ‘zero fuel cost’ , it is capital intensive . The installed cost of a wind turbine is over $3000 per kilowatt which is three times the cost of fossil fuel burning power sources. Wind turbines need an air velocity of at least 15kph to function. Moreover, wind speeds fluctuate with gusting and swirling effects. The wind turbine designs at present do not handle these conditions efficiently.

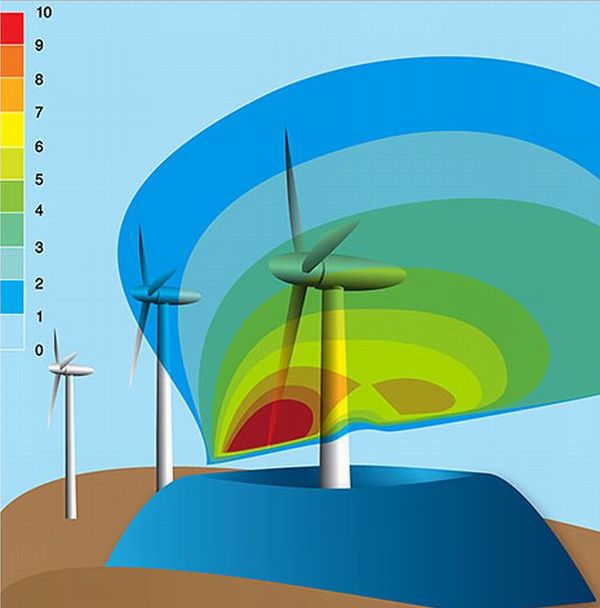

The wind farm as in the picture above needs a lot of open space between towers, that is, some half acre around each tower to ensure that steady wind streams apply on each set of rotor blades and to provide space for the maintenance take down of the rotors. Researchers are working on several aspects to improve the efficiency of wind power generation . Some of these changes are evolutionary while others attempt to be entirely new approaches.

What’s next

First some interesting evolutionary changes:

1. GE, a leading wind turbine manufacturer, has launched a suite of electronic controls and software products to improve efficiencies. The WindBOOST control system that can be retrofitted on their 1.5 MW wind turbines continually optimizes the rotational speed with power demand from the grid and is said to increase output from 1.5 MW to 1.6 MW. Related products like WindInertia , aim to stabilize the operation of their 1.5 MW and larger wind turbines in conditions of demand surge or fall by utlizing the inertial energy in the rotating blades. Another product named WindLayout helps layout planning of the wind farm to optimize wind power generation.

2. Other such evolutionary efforts include one by Purdue University and the Sandia National Labs to embed sensors on the blade tips to monitor wind forces and signal for the wind turbine to turn to optimize its position for increased power output. Catch the Wind, a Virginia based company, installs optical beam lasers on wind turbine towers that can sense wind direction 300 meters away and gain time for the wind turbine controls to respond. Another research team from the University of Syracuse and Minnesota has found that the wind resistance on rotor blades can be reduced if tiny grooves of 40 to 225 microns are formed on the blade surfaces by an etching process or by the deposition of a coating. This is said to improve turbine output by 3%.

What difference will it make:

Such continuous improvement is necessary to advance the technology and often work on such advances lead to new breakthrough changes that are needed to promote wider adoption of wind turbines.

Problems:

The problems with evolutionary change as always is that it is slow and the improvements appear small in relation to the cost and time in making the change.

Some new approaches to increasing wind turbine performance

3. Plastic and Steel Funnel

One interesting new idea by Leviathan Energy Inc is to build a plastic and steel structure, called “Wind Energizer“, near the base of the wind turbine tower to channel and direct the wind to the “sweet spot” of the blade to increase the energy output.The picture shows a computer model depicting that the Wind Energizer has increased the wind velocity near the tips of the blades in comparison with the centre of the rotor. Leviathan Energy claims an amazing 15-30% increase in turbine output besides longer life for the turbine blades by reducing shear forces on them.

4. The Wind Lens

Another new approach that has attracted attention is that of the Wind Lens by researchers at the Kyushu University, Japan.

The picture above shows a series of circular hoops of 112 meter diameter on a floating hexagonal platform. The hoops have ribs that capture the wind and turn the turbine blades at the centre. Prof. Yuji Ohya of the university says that the hoop intensifies the wind just as a lens intensifies light rays and suggests that energy output could be three times higher than the present wind turbines.

What difference will it make:

Such breakthrough concepts need to be worked on to take the technology from its present limits to new highs.

In summary

While the growth of wind energy industry by 31.7% is heartening, it remains three times as expensive as fossil fuel power plants. The world needs new technologies, both evolutionary and new concepts, to achieve breakthrough reduction in cost to enable wider usage of wind energy.