The need for cheap solar power

Over the last decade, people have become much more conscious of how they use energy, and the trend for using gadgets and gizmos that are more efficient, more effective and sustainable is on the rise. However, scientists and researchers have been looking for ways to make components used to manufacture solar cells as environmentally friendly as possible and the silicon solar panels that have traditionally been used in most photovoltaic systems are an expensive material to work with and it takes a lot of energy to manufacture them. Developers have now created an alternative to the silicon-based solar cell and these organic solar panels look to revolutionize the manufacturing process of the solar panel itself.

Organic solar cell as an affordable solution

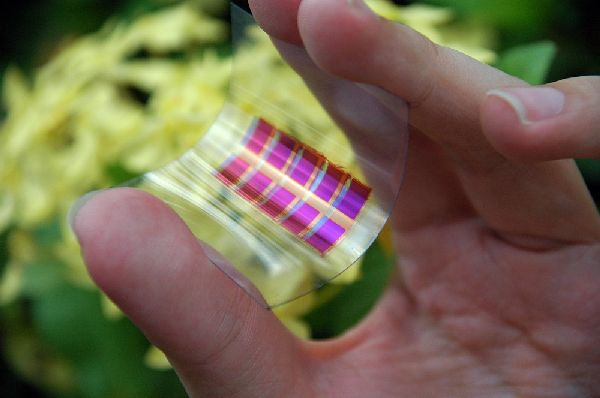

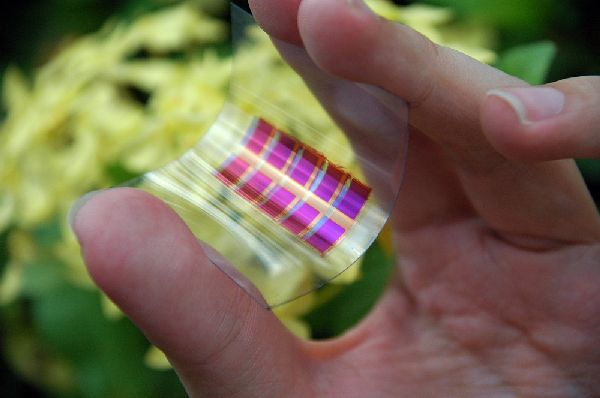

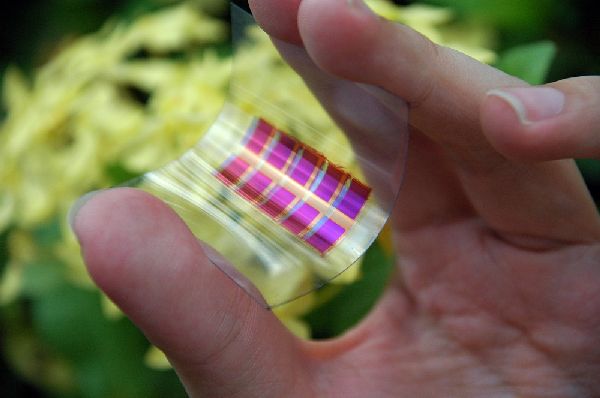

Commonly known as plastics, the carbon compounds used in these new organic solar cells are more flexible and lighter in weight because they require much less energy to create. These organic solar cells are actually greener than the silicon PVs. Another benefit of this technology is that the organic photovoltaic actually possesses ability to choose the molecule that absorbs sunlight more efficiently. This means that the organic solar cells can actually be made to be up to 1000 times thinner than the silicon-based solar cells which would lessen the amount of material used to manufacture them. This would allow manufacturers to ‘print’ solar cells onto rollable panels that can be easily transported and would need to be simply unrolled on the buyers’ roofs. This also means that these organic PVs can be used in clothes and tents and a company called Konarka is already trying to use organic solar panels like these.

Key developments

1. Gold nanodots layer to improve organic solar cell efficiency

Developer: International research team of France and Denmark

Description

According to new research published in the journal, Gold Bulletin, the efficiency of organic photovoltaic cells may be improved by using indium-tin oxide (ITO) coated glass, which has a layer of gold nanodots on its surface. Written by an international team from Denmark and France, this paper explains how a discontinuous film of just 0.5nm thick gold nanodots is sufficient to significantly improve the solar cell’s performance. Organic solar panels are currently the focus of significant scientific interest and have strong potential as a low cost means of generating solar power. Gold is an ideal candidate for conductive layers in photovoltaic since it contains a rare combination of properties that provide it compatibility with other elements, chemical stability and high conductivity, which has prompted its use in the electronics industry. However, the unequal energy alignment between the organic semi conductors responsible for conducting photogenerated charge carriers to the electrodes and harvesting light and the transparent ITO electrode severely limits the efficiency of these cells at present.

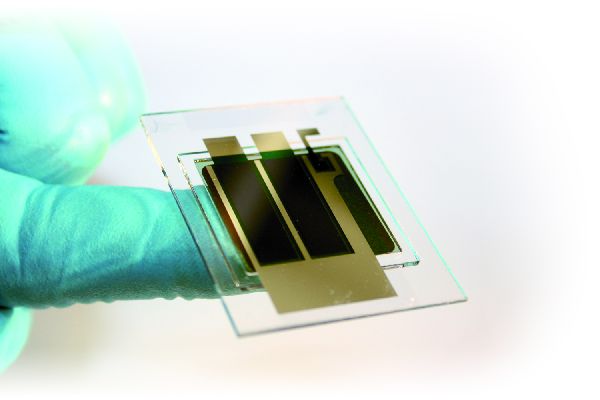

2. Heliatek achieves 9.8% organic solar cell efficiency

Developer: Heliatek

Description

Heliatek GmbH has focused on the development of their PV on low temperature processes within the deposition of small molecules. The organic solar panels developed by the company have reached the level of efficiency of conventional amorphous silicon solar cells. Manufactured with a low-temperature deposition process, a 1.1 cm² tandem cell developed by Heliatek achieved an organic solar cell efficiency of 9.8% which is a record in itself. Heliatek plans to gradually integrate this new cell construction in their manufacturing process in the second half of 2012.

3. Polymeric material developed for organic solar cells

Developer: Institute of Materials Research and Engineering of the Agency for Science, Technology and Research, Singapore

Description

Researchers from the Institute of Materials Research and Engineering of the Agency for Science, Technology and Research in Singapore have created a power conversion efficiency polymer that offers higher charge mobility as well. With a high solar power conversion efficiency of 6.3%, the polymer can compete with commercially produced semi conducting materials since it delivers the same high charge mobility.

What needs to be improved?

Organic solar panels currently do not produce as much electricity as silicon-based cells do though they are decidedly greener. Currently, organic PVs only produce around a fifth of the energy that a silicon-based PV does. This lack of efficiency and extraction and generation of electrical charges has prevented developers from using organic PVs as a viable alternative to the silicon solar cell. Another deterrent for manufacturers looking to manufacture organic PVs is the fact that they have a shorter life span in comparison to conventional silicon PVs.

What’s in the future?

1. Researchers develop cheap and easy to mass produce ‘solar-paint’

Developed by a team of researchers from the University of Notre Dame’s Center for Nano Science and Technology (NDnano), the ‘solar paint’ is composed of nanoparticles of titanium dioxide (TiO2) that is coated with photon-absorbing compounds like cadmium selenide and cadmium sulfide. This material was suspended in a water-alcohol mixture and made into a paste which was brushed onto a transparent conducting material. When exposed to light, this paint created electricity. Though the conversion efficiency of commercial silicon solar cells have still not been reached by this solar paint, the development can potentially revolutionize the solar energy sector.

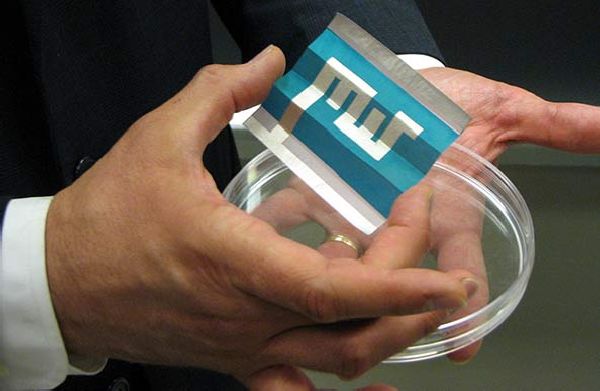

2. Printable solar cells

Researchers at the newly founded Eni-MIT Solar Frontiers Research Center of the prestigious Massachusetts Institute of Technology (MIT) have used an inkjet-like printer technology and an organic nanoscale semiconductor material to print a solar cell on paper. The researchers have successfully made 1.5-2% efficient cells using carbon-based dyes that can absorb different wavelengths of incident sunlight via multiple layers of these cells. If researchers can boost their efficiency, these thin-film solar cells would be printable on metal, paper and plastic and would potentially be useful in making paper-thin OLED display screens and monitors.