According to a study conducted by the scientists at the Imperial College London, ionic solvents have slippery properties that could save approximately 80 percent energy consumed during biomass processing. This would also help to cut the current cost of producing biofuels by ten percent. They claim that a slight amount of lubrication could result in a relatively more sustainable process of biofuel manufacturing. An elaborate explanation follows after the break.

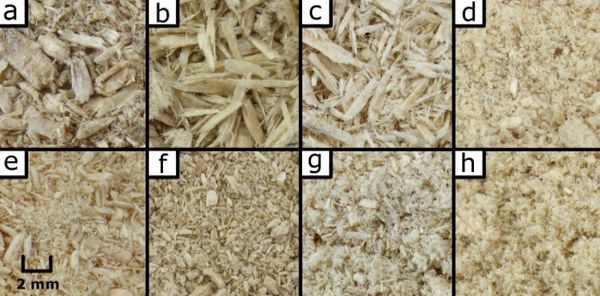

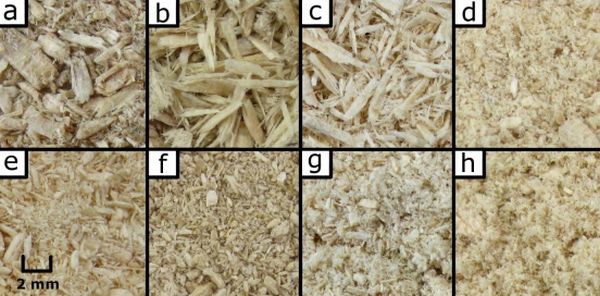

Biofuel production entails a number of stages that use varied amounts of energy. One such stage is when the chunks of timber are converted into a soup of fluids using an industrial grinder. This stage is among the most energy intensive stages and if timber will be treated with ionic solvents, the energy requirement will be reduced considerably. This can primarily be attributed to the way, in which the fluids will lubricate the wood chips during grinding.

Biomass products are considered highly environmentally friendly and they are sourced from fast growing tree species like willows and pines. These products include, oils, biomass derived plastics, polyesters, etc. To ensure that biomass continues to live up to its green expectations, the first thing that needs to be ensured is that the manufacturing process itself is sustainable and insinuates a reduction in its environmental impact.The action of ionic solvents is sure facilitates improved efficiency.

Talking in terms of numbers; in general grinding a ton of biomass costs around $12, and, after application of this method, the cost be reduced by a whopping $9.6 , which marks 80 percent reduction in cost.

Via: Imperial