What’s happening now

Solar photovoltaic cells have always been rigid silicon cells protected by a glass panel, and mounted on roof tops on brackets slanted to face the sun. This image of the solar energy harvesting device is undergoing rapid change with the emergence of solar photovoltaic cells built into flexible plastic films that can be formed into a variety of shapes. In the picture above, the windows of this building are covered with plastic photovoltaic film to produce some of the electricity that the building uses.

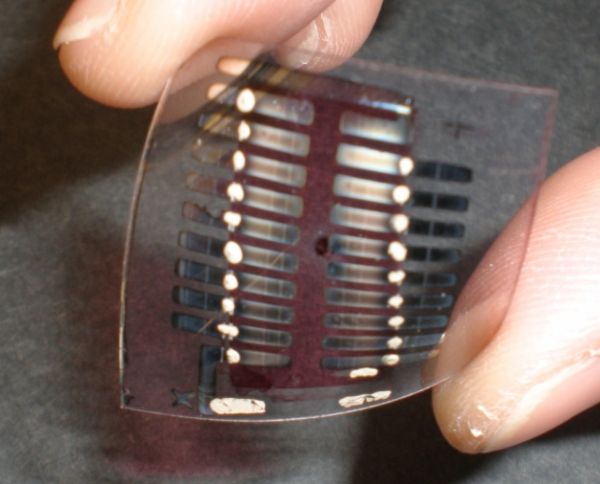

A plastic solar cell is typically made of two layers of photovoltaic material that absorb energy from different parts of the solar spectrum. This is connected with a transparent layer of titanium dioxide that serves as the conductor. This solar junction is enclosed in a plastic film that protects it from air. The manufacturing process for these flexible films is roll-to-roll printing like the printing of newspapers and is cost effective. The film is continuous and is flexible that permits it to be used in a variety of applications that are not possible with the rigid solar cells.Some examples of these new applications are discussed below.

The global research efforts into plastic photovoltaics are aimed at the two crucial problems. The first is , of course, the cost. Photovoltaic power has been 10 times as expensive as fossil fuel based power sources. The plastic photovoltaic manufacturing process and lower materials usage suggest a lower cost, but no hard numbers are yet available. The second concern, specific to the plastic photovoltaics is the durability which also translates into cost.

The inherent nature of the plastic film would suggest significantly lower lifetimes than the 20 year life for rigid silicon solar panels. The silicon panels behind glass do not show any significant degradation of performance with time whereas all plastics have this problem. This would suggest that the power output from a plastic solar film could decrease with time, which would be an additional issue with its use.

A further factor is the efficiency of energy conversion. For plastic solar photovoltaics, this efficiency is in the 6-8 percent range while for rigid silicon solar modules it is in the 15-18 percent range. If the cost of plastic photovoltaics were to be half than that of silicon solar modules, the efficiency gap would be immaterial with the plastic scoring on its other attributes of flexibility and, therefore, use on surfaces other than rooftops.

Trends

1. Flexible plastic panels create electricity

Shown in this picture is the roof of a bus shelter in San Francisco covered with flexible solar film termed “Power Plastic” made by Konarka Technologies of Lowell , Massachussets. Konarka founder and Chairman is Prof Alan J Heeger who won the Nobel prize in 2000 for his work on conductive polymers.

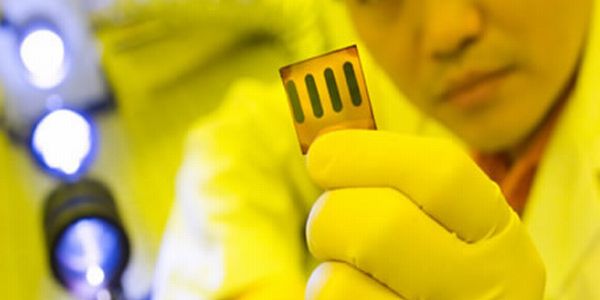

Konarka is said to use Organic Photovoltaic materials ( OPVs) printed on flexible transparent or translucent plastic films. The surface of the film is textured to create micro ridges that are said to enhance light absorption. The manufacturing process needs the micro ridges of the two layers of the film to be perfectly aligned to ensure improved light absorption. Konarka’s film has recently achieved a record 8.3% efficiency in laboratory tests beating the previous score of 8.15% by a California based start-up company.

Konarka has also built demonstration projects for the application of this technology. They have installed 7 large windows ( 56 ” x 67″ ) on their headquarter’s building with plastic photovoltaic covered glass. They had previously covered one vertical wall of their facility in Florida with “Power Plastic” film.

2. Light activated power plastic to lighten a combat soldiers pack

The combat soldier in a modern war theater uses a large variety of electronic equipment for sensing, surveillance, communications, search and destroy functions for survival. All this electronics, however, needs batteries that are heavy and that run down. Field recharging may not be practical in the absence of power sources which then leads to the need of carrying of spare batteries.

Konarka Technologies has signed a $1.6 million pilot contract with the US Army to provide backpacks and tents made with their Power Plastic material that can harvest solar energy and can recharge batteries. Such trials could yield products for civilian use too, such as on laptops or mobile phone cases that could harvest light energy and recharge batteries.

3. Giving plastic solar cells an energy boost

Looking at the possibilities with plastic photovoltaics, various teams of researchers are working on alternative technologies to achieve greater efficiency at lower costs. Solarmer Energy of El Monte, Calfornia, is said to be on track to reach the significant milestone of 10% efficiency this year. Konarka, as noted above, has reached 8.3%. Yue Wu, the company’s Managing Director with Prof Luping Yu of the University of Chicago are working to engineer a range of polymers that can absorb a wider range of wavelengths so that solar energy can be absorbed not only from visible light but also from the infra-red spectrum that contains as much as half the total energy in solar radiation.

4. New plastic solar cells mimic the veins in tree leaves

Researchers at the Wake Forest University have come up with a process to embed nano filaments of conducting plastic within the light absorbing material of plastic solar cells. These nano filaments conduct put the electrons preventing the heat production in the light absorbing layer. This permits the light absorbing layer to be made thicker . The Wake Forest team has achieved an efficiency of 6% and is working to take this higher.

The Concept

Plastic Solar Cells appear to be on the verge of emerging from the laboratories and research journals into everyday applications. From the first concepts being discovered in the early 1990s to the present day position described above, is the typical development lead time for any new technology.

The further work already under way will, hopefully, find means to reduce costs of solar power to achieve cost comparable with those of utility power (“Grid Parity”) by 2015. That is the target for the US Government’s Solar America Initiative. The developments in plastic solar cells will contribute to meeting this objective.

The advantages

These are flexible and light and can be applied to any surface including vertical walls, curved surfaces and so on. They could even be sprayed-on keeping installation costs very low. Conductive cells can be printed on plastic film in a roll-to-roll process that is said to be at low temperatures and environment friendly.

Low cost plastic materials are used in the manufacture of plastic solar cells. Only a few tenths of a micron thickness of conductive plastics are needed. From the materials availability and usage standpoint, this technology should be a winner. The cell efficiencies are being improved to 10% by improving energy capture from the red/ infrared part of the solar light and by other techniques such as etching or micro ridges formation on the plastic to increase energy capture.

The impact

Plastic solar panels clearly add a vast new dimension to our ability to harness solar energy from beyond the confines of the rooftop installations that are the norm with rigid silicon cells. The two issues of cost and durability are being worked on by researchers around the world. Once viable solutions emerge for these two issues, we should see flexible solar panels becoming visible in wearable and even disposable energy sources for a variety of applications.