Man is continuously trying to invent products that will help him lead an easy and sustainable life. The latest green invention in the field of science is of Smart Plastic made by researchers at Case Western Reserve University in Cleveland. This material has self-repairing capabilities, i.e., the plastic can repair itself if put under ultra violet light.

According to scientists, as this material has the ability to repair itself, it can efficiently be used as car, floor or furniture paint and even in medical surgeries. The presence of small molecules in the structure makes it different from the normal plastic, which is actually made of long molecules. The smaller molecules in the Smart Plastic are held together by a molecular glue. Under ultra violet light, the structure is unglued, thus, giving it self-repairing abilities.

Trends

1. Sun-Powered Self-Healing Plastic – The End of Scratched Gadgets?

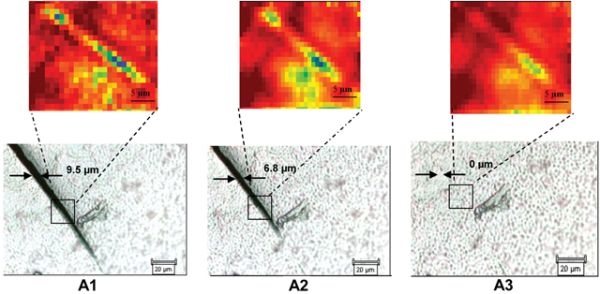

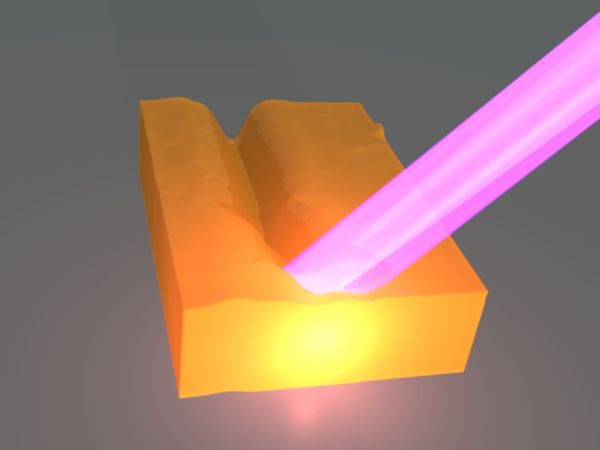

Two scientists from the University of Southern Mississippi have made a plastic that can repair its scratches with the help of ultra violet light. What they actually did was that they used polyurethane to make the plastic body. Polyurethane is an elastic polymer and resists scratch. With this polyurethane, they combined OXE and CHI. OXE breaks down easily because of its unstable structure and CHI is UV sensitive. So, when a material is scratched, OXE breaks to give reactive ends, which are then sealed with the help of UV-sensitive CHI under the ultra violet light.

This plastic heals itself in just half an hour under a 120 W ultra violet light. If it is confirmed that the product is safe and recyclable, it will be a huge success.

2. Self-Healing Plastics Could One Day Repair Planes in Flight

Engineers at Bristol University, UK have developed a plastic that can heal itself and it can be used in the manufacture of planes. This special feature of the plastic is due to the presence of micro tubes of epoxy resin, which are inserted in fiber-strengthened polymers. Whenever there is a scratch, this resin comes out of the tubes and fills the crack. The engineers have also mixed an ultra violet pigment in the resin so that the healed cracks are visible to human eye, which can later be repaired permanently.

3. Plastic Heal Thyself: Materials Mimic Vascular Networks

The concept has been derived from the biological process, where we bleed when hurt and have the capability to heal ourselves. Scientists at the University of Illinois at Urbana-Champaign have made a plastic, which has been inspired by human body, and it repeatedly heals itself.

This is because the new plastic has a vascular network. Scientists have made micro channels in the substrate and filled it with a reactive fluid. This substrate is then covered with a brittle epoxy material that contains catalyst. Whenever the plastic is scratched, the reactive fluid comes out and heals the crack. Although the technology is very useful, its cost makes it impractical.

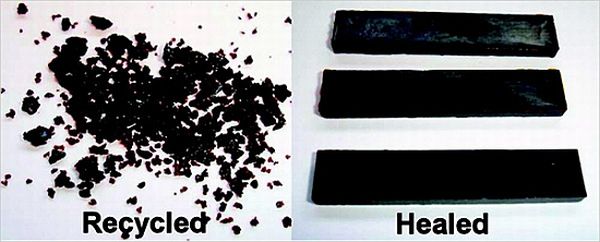

4. Researchers develop self-healing plastic for sustainable electronics

As electronic components are made of thermoset resins, they decompose when heated, thereby becoming a plastic waste. However, chemists at the University of Groningen have developed a new plastic that can be used to make electronic components and at the same time is recyclable. This plastic also has the ability to heal itself.

This plastic is made of Polyketones that are cross-linked with an organic compound called bismaleimide. The cross linkage is reversible, so when heated at 300 degrees Fahrenheit, the material becomes unlined and then cools off to form the link again. According to the researchers, this plastic has the ability to be recycled seven times without the loss of any characteristics.

The benefits

• This Smart Plastic can have benefits in several fields. As the Smart Plastic has the capability of repairing in less than an hour, it can be used in packaging, fashion or biomedical industries.

• Unlike normal plastics that require heat to be repaired, the Smart Plastic repairs using ultra violet light. This light can actually be focused only over the area to be repaired, leaving the other parts untouched.

• Another use of this plastic can be in making large lenses, because when healed the repair will remain transparent. This plastic can also be used to make clear domes over aircraft radar.

• This new innovative Smart Plastic can be advantageous over other plastics because it will be able to heal itself without even leaving a mark of the fracture.

The lowdown

Although the Smart Plastic has lots of advantages, few facts about it need to be confirmed before releasing it commercially.

First, it should be known what will happen to the plastic if it is scratched on the same place second time. Second, the shelf life of the new plastic needs to be determined. Third, researchers should confirm whether the product is recyclable.

The Impact

As the Smart Plastic has the ability to heal itself in a very short time, it can be used in several industries. The new plastic has smaller molecules attached with molecular glue, making it easy to be repaired under ultra violet light. If all the doubts about the product are cleared, it is sure to become successful. Due to its self-repairing abilities, this product can make work easier for those who deal with plastics. If the product is recyclable, it will actually help in the reduction of lots of plastic waste.

Right now, we can wait and hope to get positive feedback for this product, so that it soon becomes available commercially.