Introduction

One of the challenges in wider adoption of clean energy sources like solar and wind has been that the power output is not continuous. Solar generation needs sunshine which is only in the daytime. It also varies with the weather as cloudy days generate lower output than bright clear days. Similarly, wind energy depends on a the availability of at least 12 meters/hour wind speeds. Wind speeds drop, eddies and swirls cause the wind direction to shift such that the wind turbines become less effective.

These issues have meant that the clean energy source needs to be supplemented by fossil based power, negating the very purpose of adopting the alternative energy source.Some of these issues could be resolved if there was a way to store the energy that a photovoltaic module or wind turbine produces that could deliver the energy to the user at the times that the solar or wind energy does not generate adequate power.

Batteries are the most common energy storage device that we use.The batteries now used, the Lead Acid batteries that are used in cars for starting, the Nickel Cadmium batteries used in Railway Engines, suffer from the problem that their energy storage capacity is limited and they have a poor power to weight ratio. For example a 22KWh battery used to power an Electric Car weighs some 150kg. It is estimated that if the city of New York that consumes 13,000MW were to be provided battery back-up, it would need a battery bank that will occupy 60,000 square meters of space.

Trends

1. MIT’s liquid battery for renewable energy plants

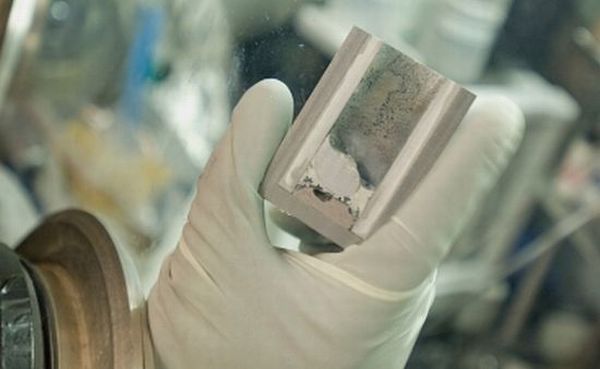

All this could change with a new approach to battery technology by Professor Donald Sadoway of MIT’s Materials Chemistry department and his team. In a radical departure from conventional battery technologies that use soild materials as electrodes, the MIT team has used molten Antimony as one electrode at the bottom in the above pictures and molten magnesium as the other electrode, the top layer in the pictures. In between the two electrode layers is the layer of the electrolyte, which is molten sodium sulfide.

Since the three liquids have different densities, they form distinct layers and do not mix into each other. When the battery is discharged, the Antimony and Magnesium electrodes are thin layers while the sodium sulfide electrolyte layer is thick. When the battery is charging by drawing power, magnesium ions in the electrolyte gain electrons and become magnesium metal that rises to the top. The antimony ions lose electrons to become antimony metal and sink to the bottom .

In the picture above, this is depicted in the layer thicknesses. When the battery is fully charged, the electrode layers are thick while the electrolyte layer is thin. When the battery then discharges, delivering energy, the process reverses with the electrodes thinning and the electrolyte layer getting thicker. The materials in actual use now are different from the ones named above and won’t be disclosed until patent applications have been filed. Prof Sadoway, however, says these will be earth-abundant low cost materials .

In the laboratory model that was demonstrated in Feb 2009, an external heat source was needed to keep the electrodes and the electrolyte molten at temperatures of 700 degrees C. Prof Sadoway says that in actual application, the high current flows through the battery would itself create enough heat to keep them molten. Prof Sadoway says that this technology was inspired by the Aluminium smelter. In an aluminium smelter a mixture of alumina ( the oxide) and cryolite is contained in a pot through which very high electric currents of 100,000 to 150,000 amperes are passed.

In this electolysis process, carbon from the anodes combine with oxygen from the alumina and the molten Aluminum formed sinks to the bottom of the pot and gets taken out as molten aluminum. The MIT team says that the use of molten metal as the electrodes increases the current densities possible by an order of magnitude compared with solid metal and is the fundamental breakthrough in the technology. Also since the concepts are adapted from the smelter technology that has been known for many years , this new technology has less unknowns for commercialization.

Initial research was funded by ARAP-E ( Advanced Research Projects Agency – Energy). In 2011, a start-up company named Liquid Metal Battery has been formed with the goal of commercializing the battery within 5 years at a cost not exceeding $ 250 / kWh. Considering that a photovoltaic installation costs, at present $11,000 / kWh , this additional cost that adds to versatility in use of the solar power would be well justified. The start-up company is said to have Microsoft Chairman Bill Gates as one of its investors.

2. Another MIT liquid battery that can be “refueled”

Prof Ming Chiang , also of MIT and his team have come up with a completely different approach to liquid batteries. In their concept, based on the proven lithium-ion battery technology, the charged lithium ion anode and cathode particles are suspended in an electrolyte medium and stored in two separate tanks. When these liquids are forced to interact through a porous membrane, they exchange ions and generate electricity.

Once the interaction is complete, the spent liquid suspension can be pumped out and fresh liquids pumped in, in a few minutes. The spent liquid suspension can be recharged and can be fully recycled. This liquid suspension has been termed “Cambridge Crude”. This technology was initially developed with by an MIT offshoot company named 24 M Technologies with a $16 million grant from the Department of Defence.

This development applies particularly to the battery systems to power electric vehicles and can overcome the major drawback of battery capacity limiting EVs to a maximum of 100 miles driving needing a 3-5 hour recharge stop.

3. Prof Daizi Zheng’s Coke powered mobile phone

.

While the two MIT projects for liquid batteries talks of storing and delivering kilowatts of power, this demo project for Nokia by Prof Daizi Zheng, a Chinese researcher sounds like a high school prank project. It claims to recharge a Nokia mobile phone battery with Coca Cola. The phone is said to use a “bio-battery” that contains some enzymes. When in contact with a sugary liquid (hence the Coke), the enzyme breaks the sugar into hydrogen and oxygen while releasing energy that charges the bio-battery. No details are disclosed .

The benefits

Liquid batteries, both for the application of storage of clean energy generation plants and for Electric Vehicle applications address a key problem that limits wider adoption of these “green” technologies. The initial work shows great promise and there should be no major obstacles to scaling these up to commercial use.

The Lowdown

Many questions will remain in respect of the cost of these new batteries, their life in terms of charge discharge cycles and also if there are issues in relation to disposition of damaged or end-of-life cells. While answers to these questions will be found by researchers, there will be the trend for newer technologies to be announced promising better or different benefits and those could attract the interest and funding that is needed to mature these technologies.

The Impact

Major new developments in realizing a liquid battery has been announced by two separate teams from MIT, one addressing the energy storage market for renewable energy sources and the other for electric vehicles. Commercialization is a good 5 years away.