Wind energy is one of the best renewable sources of energy that we can get on our planet. We usually don’t see wind turbines mounted onto the rooftops. But if you have one for you, paying the electricity bill should be a breeze. However, people often keep wondering if wind energy is a bit too expensive. Well, that’s not always the case as there are many alternative ways to utilize it.

The windmills that you see in the open would definitely cost you a fortune. On the other hand, if you create something like your own DIY Vertical axis wind turbine, then it’s a piece of cake. It would not only help you in contributing to green energy, but it would also help you in enhancing your technical knowledge. It is one of the perfect projects that you can work on with your teenage children and teach them sustainability at the same time.

The Significance of Wind Power

Statistical figures say wind power (providing 2.5 percent of total electricity) has reached an all-time high worldwide consumption with 197 GW capacity and 430 TWh of total energy production. Now, for comparison’s sake, the combined capacity of wind facilities around the world just marked at 17.4 GW in 2000. You can attribute this exponential increase (more than 11 times in 11 years) to better technology, effective administrative measures and in some cases efficient user contribution.

5 DIY Vertical Axis wind turbine designs to generate clean energy

So let’s get out our rusty tools and check out the 5 fascinating DIY Vertical Axis wind turbines (VAWT) contrived by the ‘common man’.

1. Homemade DIY vertical axis wind turbine from PVC pipes

Created by Instructables user Faroun, this unique (and dirt cheap) contraption combines recycled garage elements to make a full-fledged vertical axis wind turbine. According to the creator, the V8-4” turbine was ‘salvaged’ from PVC pipes (cut to shape), permanent caps from sewer pipe aisles, an axle from an old bike, a tricycle wheel, a DC motor, electric wire, and screws. The final product with a cost of paltry $182, has improved RPM and greater blade area, while Faroun aims to make it capable of generating 100 watts at 35 km/h of directional wind speed.

Created by Instructables user Faroun, this unique (and dirt cheap) contraption combines recycled garage elements to make a full-fledged vertical axis wind turbine. According to the creator, the V8-4” turbine was ‘salvaged’ from PVC pipes (cut to shape), permanent caps from sewer pipe aisles, an axle from an old bike, a tricycle wheel, a DC motor, electric wire, and screws. The final product with a cost of paltry $182, has improved RPM and greater blade area, while Faroun aims to make it capable of generating 100 watts at 35 km/h of directional wind speed.

We all know that wind turbines need some kind of a brake mechanism to prevent them from rotating uncontrollably. With no such setup being installed, we fear that the turbine won’t be able to withstand high wind speeds. But since the turbine is only a $200 venture, we don’t think there is anything wrong in starting your green life with this.

2. Lenz2 vertical axis wind turbine

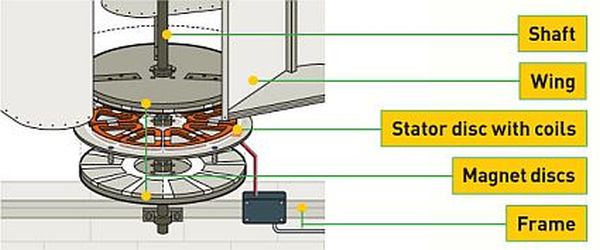

The Lenz2 relies completely on easily available household materials for its construction. At PopSci, Lenz2 was at an exhibition for a cost of less than $300. For the wing, it utilizes a primary component of plywood. This is in connection with 4 ft rods having a cover of sturdy aluminum. For the alternator, there are two separate steel discs with magnets on them. On the other hand, you would find copper wires taped to a plywood one. All of them are fixed to the main shaft around their axis. Other clamps and welding were used along the shaft, to hold the DIY contraption in one piece. This singular component in turn can generate (by connecting rectifier to the alternator) 50 kilowatt-hours of electricity per month for 8 battery pack, at optimum wind speed of 10 km – 36 km/hr.

Here is how you should build one for yourself:

a) Construct the wings:

Carefully cut teardrop shapes from plywood and connect them with four-foot rods. Cover these wings with aluminum.

Carefully cut teardrop shapes from plywood and connect them with four-foot rods. Cover these wings with aluminum.

b) Build the alternator:

This is a bit tricky. There is no difference between normal pieces of wood and the one in the design if the design is not able to harness wind and convert it into electricity. An alternator does this work. To design one just glue magnets to two steel discs. Tape copper-wire coils to a plywood disc and slide all three discs over the shaft.

c) Attach other parts:

Clamp both ends of the shaft to the rectangular frame. Weld the wings’ arms to the bottom of the alternator, as well as to a steel disc at the top of the turbine.

d) Mount the frame:

After the completion of step 3 you are almost done, the final step is to attach cables to the frame arms and stabilize with sandbags.

e) Power the house:

The last step is to use the generated power to power your house. Wire the alternator to a rectifier. This will convert the power into DC voltage. Connect this line to batteries. The wind turbine takes four to six hours to fully charge a bank of eight batteries.

3. The Zoetrope VAWT

Image Source : applied-sciences.net

Image Source : applied-sciences.net

This device consists of locally available hardware components like stove pipe, metal brackets, plastic sheet, and even a trailer hub. It has a very low cost design and zero emission water heating. You can regulate the power output of the simple yet sustainable Turbine to suit the micro-climate and characteristic of the site. On testing, it shows an output of 150-200 watts, while the nigh perfect wind (gust) velocity which it requires is at about 25 m/sec.

4. VAWT made from scrapped rechargeable drill

Above Secret Post user Citizen Smith has designed a VAWT from the stripped form of a rechargeable drill (including the embedded circuitry and body shell). He put to test this hollow drill by another cordless drill, with a final result of 150-200 rpm at 11.5 V. With this sufficient rotating mechanism, he went on to contrive a helical turbine design made from corrugated cardboard. The wing section was then covered in fibre-glass mat and resin for the finish of mold. He could then utilize them (for casting blade components) into the 3m high helical rotor structure.

5. 55 Gallon Vertical Axis Wind Turbine

Image Source : personal.psu.edu

Image Source : personal.psu.edu

The conspicuously bulbous 55 gallon barrels were vertically cut down through halfway for Savonius type turbine. For the vertical axle – a 3″ PVC pipe was used to be utilized as fixing component for the two halves of the barrel mounted on each other. The plastic clamps were connected with two square plywood planks with ball bearing (on the inside) for added fluidity of motion. Coming to power generation, a permanent magnet alternator was used with custom shaped gear for optimum gear ratio. Finally, a fan blade was integrated for the cooling process of the whole generator in case of higher wind speed.

Innovative Vertical Axis Wind Turbine designs you can take inspiration from

While most of us would be satisfied with above DIY designs, there are a few who would surely like to take things to the next level. And if you are one of those few, you would surely like to know what else can you do with a vertical axis wind turbine? For such curious DIYers here are few of the most innovative vertical axis wind turbine designs out there:

1. Generadoreolico: A vertical axis wind turbine system for greater efficiency

Statistically, power consumption from ‘clean and green’ wind has reached an all time high (almost 2.5 percent of worldwide electricity usage), with a whopping 197 GW nameplate capacity and 430 TWh of total energy production. And, with this righteous trend of large-scale commercialization of wind power, small scale wind generators for micro-level usage are certainly becoming all the more important. Taking into account of this inherent flexibility, Argentine designer Miriam Peterson has conceptualized the effective GeneradorEolico – a domestic vertical axis wind turbine system based on Savonius rotors.

Statistically, power consumption from ‘clean and green’ wind has reached an all time high (almost 2.5 percent of worldwide electricity usage), with a whopping 197 GW nameplate capacity and 430 TWh of total energy production. And, with this righteous trend of large-scale commercialization of wind power, small scale wind generators for micro-level usage are certainly becoming all the more important. Taking into account of this inherent flexibility, Argentine designer Miriam Peterson has conceptualized the effective GeneradorEolico – a domestic vertical axis wind turbine system based on Savonius rotors.

Savonius rotors can utilize the force of the wind and convert it into a torque on a rotating shaft. In this system, three separately intricate Savonius rotors (connected to respective generators) will be fixed by sturdy cables to a central module. The central module in turn will be connected to a storing point with an integrated 12V, 220A battery pack. The basic design alludes to the intrinsic aerodynamic property of the rotors in their multiple forms, which will augment the magnitude of wind energy that is to be transformed into clean electricity.

According to the designer, the generator can harness the wind at a paltry 4m/s, as this instills a whopping 50 rpm in the efficient rotors. The total output capacity of the setup can be marked at 3 KW. But the predicament lies with the safety factor, especially when high speed rotating blades are placed in a domestic environment. Hence, the designer has also adroitly thought of horizontally placed security wheels that can warn users by their conspicuous rotation. Moreover, with their perforations, the total lateral drag is cut down, thus accentuating upon the overall lightness of the mechanism.

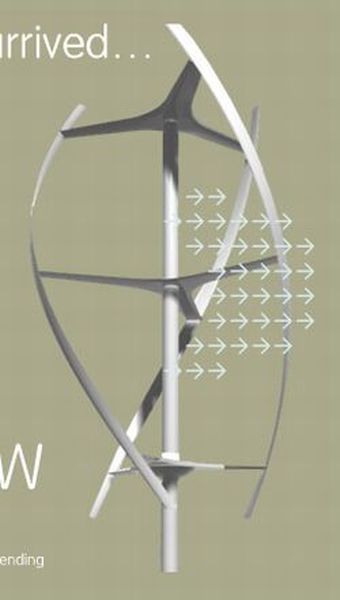

2. Quietrevolution: Wind turbine with vertical-axis

Here lies the real aesthetics of wind turbines. This elegant, ‘S’ blade designed vertical-axis wind turbine will surely provide a solution to both tourism industries and, wind-power generating industries and environmentalists. The amazing design of this wind turbine, named ‘Quietrevolution’ will not make the tourism industries worry of marring the nature’s beauty, but will add to it.

Here lies the real aesthetics of wind turbines. This elegant, ‘S’ blade designed vertical-axis wind turbine will surely provide a solution to both tourism industries and, wind-power generating industries and environmentalists. The amazing design of this wind turbine, named ‘Quietrevolution’ will not make the tourism industries worry of marring the nature’s beauty, but will add to it.

Thanks to XCO2 for designing and developing this unique and innovative wind turbines. XCO2 is an established low-carbon energy consultancy and engineering firm. These turbines are also technologically sophisticated as are virtually silent and free from vibration. Thus, these turbines are ideal for installing both at urban sites and exposed locations.

The patent pending design is simple and robust, with only one moving part. Hence, it maximizes reliability, while minimizing maintenance requirements.

3. Vertical axis wind turbine that doubles as a chimney

Wind Energy is easy to harness and convert into useful power for you home. A couple of days ago we told you how to make a vertical axis wind turbine with just $300 in your pocket.

Wind Energy is easy to harness and convert into useful power for you home. A couple of days ago we told you how to make a vertical axis wind turbine with just $300 in your pocket.

Here is a vertical axis wind turbine that also doubles as a chimney. We still don’t think that this is the way to go green as if you are still burning that much wood indoors, you are not protecting the environment but suffocating the trees around your so called “Green House”.

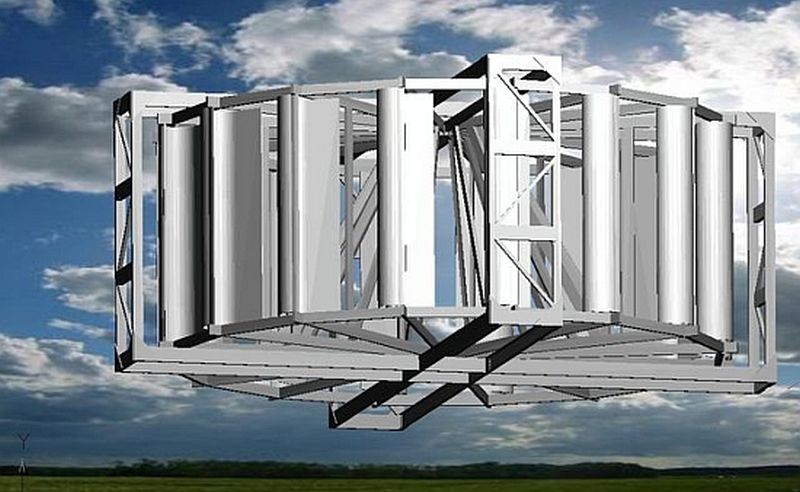

4. Vertical axis wind turbine concept

Apart from being more dependable than solar energy, wind energy has always been a secondary choice for all eco-minded home owners. Reasons include bird kills, noise and the decrease in the output when wind changes direction. A concept wind turbine designed by Industrie-SA can answer all these problems with a clever design. The vertical axis turbine is designed for urban environments having windy conditions.

Apart from being more dependable than solar energy, wind energy has always been a secondary choice for all eco-minded home owners. Reasons include bird kills, noise and the decrease in the output when wind changes direction. A concept wind turbine designed by Industrie-SA can answer all these problems with a clever design. The vertical axis turbine is designed for urban environments having windy conditions.

Having a diameter of 8m and a height of 3m, the turbine can generate up to 175MWh per year. Being vertical axis the turbines are safe for birds and are also less noisy when compared with the horizontal axis counterparts. The designers also claim that the turbines are insensitive with the direction and the force of the wind.

Final Words

Thinking about making a low-cost, easy-to-install wind power device that provides a safe and attractive method for harnessing power from the wind? Virtually all modern wind turbines convert wind energy to electricity for energy distribution. So why not follow these steps and make your own Vertical Axis Wind Turbine or VAWT that stands on the ground and can accept wind from any direction, a unit that will potentially experience high winds, above 25MPH.

Vertical–axis wind machines have blades that go from top to bottom and look like a giant two-bladed egg beaters. The advantages of this arrangement are that generators and gearboxes can be placed close to the ground, and you need not worry about the wind direction. It is easier to maintain because most of their moving parts are located near the ground and there are no emissions or pollution produced by its operation. For those who live in areas with high winds and want to curb their electric bills, this option can be highly efficient and moreover an attractive energy source.